UD-CCM will host the 24th International Conference on Composite Materials (ICCM24) as part of our 50th anniversary, at The Baltimore Convention Center. There will be a dedicated industry track, international networking opportunities and cutting-edge research and insights. Register Today!

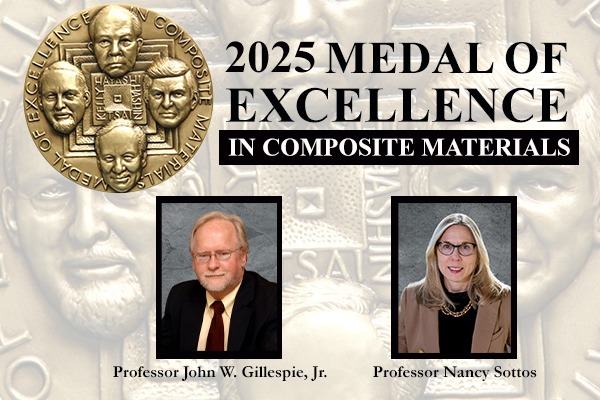

The Medal of Excellence will be awarded during the banquet at the 24th International Conference on Composite Materials

Read More

In celebration of CCM’s 50th Anniversary, join us on August 6, 2025, at Power Plant Live!

in Baltimore’s Inner Harbor for an unforgettable night honoring five decades

of innovation, research, and workforce training.

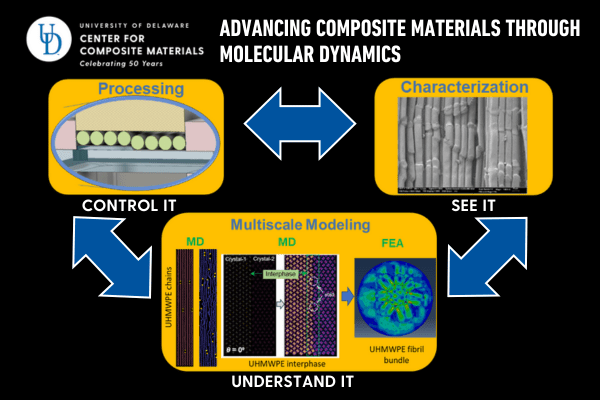

UD-CCM has been on the forefront of molecular dynamics (MD) simulations for over 15 years, modeling the behavior of polymers and composites at the atomistic scale.

Read More

are working together to develop components of the next-generation Exploration Extravehicular Mobility Unit (xEMU) spacesuit.

Read More

Services for our Manufacturing and Composites Industry Partners: process development and optimization, materials development & characterization, mechanical & impact testing and product design & development.

Read More

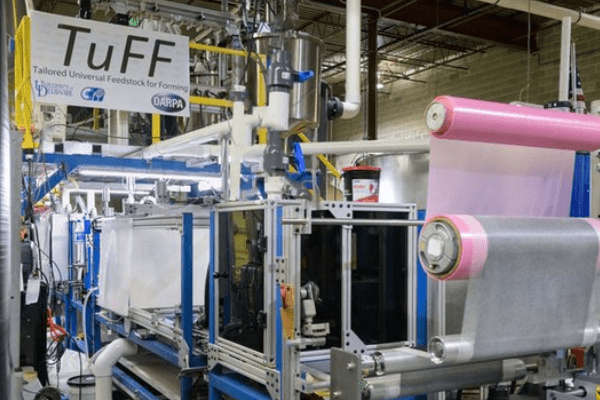

World’s strongest short fiber composite material for metal replacement achieves aerospace properties, metal-like formability in zero-waste, fiber-to-parts pilot plant.

Read More302-831-8149 • info-ccm@udel.edu