CCM Equipment

CCM’s equipment is continuously upgraded and augmented as needed to support basic research as well as applied programs carried out in collaboration with industrial and government sponsors. Within the last year, the facilities underwent a significant expansion and upgrade in three areas: high-performance computing, materials processing, and materials characterization.

Interlaken SP75 Composite Forming Characterization Press

SGI Shared Memory Supercomputer (Veyron)

|

The Altix UV1000 is the fastest shared-memory supercomputer in the world, according to its manufacturer, Silicon Graphics International. CCM researchers use Veyron to model fabric impact; model, at multiple length scales, the permeability, consolidation, and infusion of polymer composites; and simulate electromagnetic and thermal responses, impact, and wave propagation through heterogeneous materials and fluid-structure interactions. |

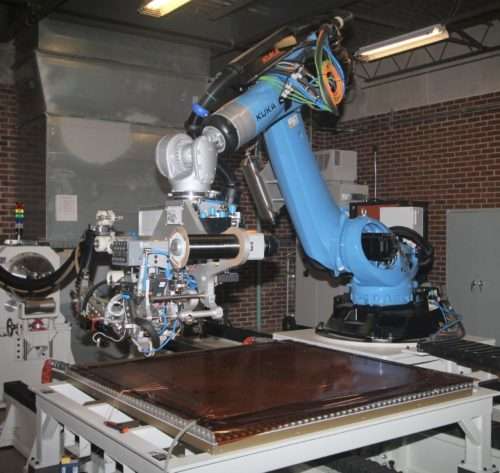

Automated Tape Placement (ATP)

|

UD-CCM has selected Mikrosam and their US representative Composite Automation LLC to deliver an integrated ATP machine for automatic placement of dry, thermoset and thermoplastic tape. Equipment specifications include placement of thin to standard ply thickness tape (up to 1 inch width), laser and IR heating with in-situ temperature control and thermal camera feedback, and horizontal axes allowing manufacturing of full-scale prototypes (10 foot length). Mikrosam is designating UD-CCM as their primary academic partner in the US providing open software and hardware access enabling R&D to develop new material solutions, in-situ process control and path/placement optimization. Robotic tape placement of composites in dry, thermoset and thermoplastic formats enables precision control of fiber orientation for high-performance applications with the benefit to meet higher production rates. Click here for more details. |

SC6100 and A615 IR Cameras

|

CCM recently purchased two FLIR cameras for temperature measurement and control: the science grade SC6100 IR camera and the industrial grade A615 system. The SC6100 camera with microscope attachment provides high-speed (35kHz) and high-resolution (640×512) MWIR imagery and can also be used for IR thermography. The system features a 50-megapixel clock that streams 14-bit digital data at up to 126 Hz in full resolution. The A615 camera is used for process monitoring, automation, and control. |

SkyScan 1172 Micro CT Scanner

|

This scanner features µm–resolution 3D images, allowing nondestructive evaluation of composite materials. The system is currently used to evaluate microstructural changes during composite processing, locate fiber in complex 3D fabrics, and detect internal damage such as cracks and fiber breakage. The system also allows the integration of a heat and mechanical stage to actuate the sample. It offers a novel tool for students, staff and industrial partners to provide insight into the composite microstructure without the time-consuming effort needed for standard microscopy. |

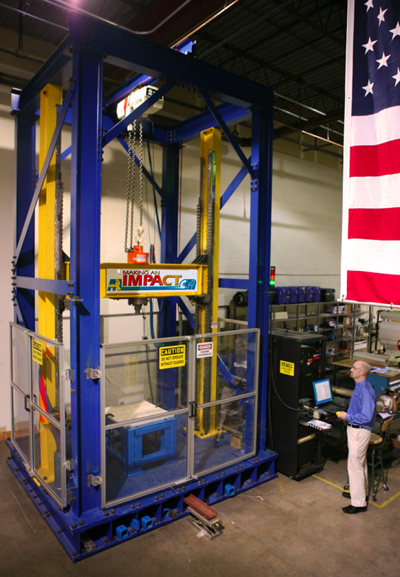

High Capacity Impact Tower

|

A custom-built high-energy drop tower system is being used to test thick composite panels, fastener assemblies, and other components of vehicle structures. The tower provides up to 37kJ of impact energy over an open (10ftx12ft) test floor and has a movable test fixture for multi-impact (durability) and damage tolerance testing. The system also has built-in lighting and isolated camera extension cranes for full-field DIC (Digital Image Correlation) analysis. |

TA Instruments Discovery Hybrid Rheometer

|

This new rheometer utilizes magnetic bearings, which greatly increases the sensitivity in measurement of torque, compared to the traditional air bearing design. The system can measure viscosities at temperatures in excess of 300°C and at sub-ambient conditions down to liquid nitrogen temperatures. The system can currently carry out cone-and-plate and parallel plate viscosity measurements and can be adapted to other forms of viscosity measurement. The main research application for this instrument is the measurement of polymer resin viscosity as a function of time, temperature, and filler content.temperature, and filler content. |

Instron 5985 Testing System

|

Outfitted with the full ensemble of fixtures, grips and T-slot base, this system has a capacity of 250kN. |

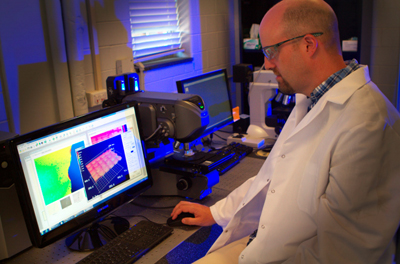

VK-X200 3D Color Laser Scanning Microscope

|

This microscope is used to capture high-resolution color images with nanometer-level profile and film measurement functions. The system provides 0.5-nm z-axis resolution on almost any material with 7-mm depth of field and is ISO 25178 compliant. The system is used extensively for accurate void and surface topography measurements as well as particle size distribution and crack and fiber filament analysis. |

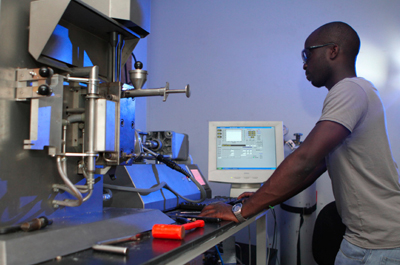

Bruker D8 Discover 2 Dimension Wide Angle X-Ray

|

This system has Bruker’s newest Vantec 500 area detector, which boasts increased sensitivity and stability compared to the older Hi-Star area detectors. The new system greatly expands UD-CCM’s characterization capabilities, enabling the determination of crystal structure in a wide variety of materials including polymers, ceramics, and metals. A major research focus for this facility will be investigation of oriented polymer films and fibers and evaluation of such parameters as degree of crystallinity, degree of crystal orientation, crystallite size, and changes in crystal structure as a function of temperature and mechanical stress. |

Micro-scale Extrusion and Injection Molding Machine

|

This machine is capable of producing small batches, 15 cm3 of material, and directly molding ASTM-sized test specimens. This process is ideal for completing studies on thermoplastic nanocomposites and polymer blends. |

Aqueous Bath Thermoplastic Prepreg Line

|

This facility addresses the current need for improved processing of high-temperature thermoplastic/carbon fiber materials. |

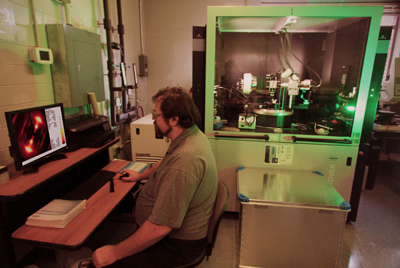

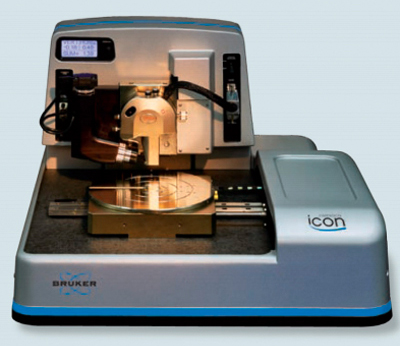

A Dimension Icon Atomic Force Microscope (AFM)

|

This microscope was purchased by UD-CCM from the Bruker Corporation, a world leader in AFM. The new AFM will extend UD-CCM’s capabilities to explore the multi-scale properties (i.e., mechanical, electrical, topographical, etc.) of materials down to molecular length scales. |

CCM Equipment by Laboratory:

Chemical Characterization Laboratory

- DiaStron Single Fiber Mechanical Tester

- Dynamic Vapor Sorption

- NETZSCH DSC

- NETZSCH Advanced Kinetics Software

- Cahn DCA 322 – Dynamic Contact

- Perkin Elmer – FTIR Spectrometer with microscope

- TA Instruments Model DHR Rheometer

- TA Instruments Model AR 2000 Rheometer

- METTLER DSC

-

METTLER TGA/DSC

- METTLER DMA 861

-

METTLER FP82 Hotstage

- METTLER XP2U Balance w/ sensitivity of 0.0000001g

Composites Preforming Laboratory

- Bally – 1000 cu-ft. Walk-in Storage Freezer

- Thwing-Albert 90 Degree Peel Strength Tester

- Surfx A250 Plasma System

- Micro Hardness Tester

- Rockwell Hardness Tester

Composites Machine Shop

- ACER AGS 1020 AHD – Surface Grinder

- Bridgeport – Milling Machine

- DoAll – Band Saw

- Empire – Glass Bead Cabinet

- Enco – Drill Press

- Enco – Sheet Shear

- Nasaturn 1340 – Lathe

Oven and Environmental Durability Laboratories

- Blue M – Laboratory Oven

- 1 Tenney Accelerated Aging Chamber – 65C Capable

- 3 Tenney Accelerated Agingn Chambers

- 3000 C High Temperature Furnace

- Blue M-Temporary Bath

- Grieve- Laboratory Oven

- Fisher Scientific Isotemp Laboratory Ovens (2)

- Vulcan A550 Laboratory Oven

- Fisher Scientific Laboratory Vacuum Oven

- VWR Laboratory Vacuum Oven

- Hotpack Humidity Chamber

- Tenny Environmental Chamber

- Linberg/Blue M Benchtop Furnace

- Terra Universal Glove Box

Manufacturing Laboratory

- Keycene LC-2450 High Precision Displacement Laser

- Amtech Ultraseam 20 Robotic Consolidation System

- Huttinger TIG 5/300 robotic induction welding system

- Matec – Four-Axis Ultrasonic Scanner

- Wabash 150 – Transfer/Compression Molding Press

- Wisconsin Oven- Convection Oven 8ft x 10ft x 8ft chamber

- Blue M -Convection Oven 3ft x 3ft x 4ft chamber

Mechanical Characterization Laboratory

- Dynatup Low-Velocity Impact Tower (2)

- Instron 1331 – Hydraulic Fatigue Test System

- Instron 1332 – Hydraulic Fatigue Test System

- Instron 4484 – Static Load Frame

- Instron 8562 – Electric Actuator Test System

- Instron 5567 – Table Mounted Test System

- Instron 5985 – Static load Frame

- Tenney – Environmental Chamber

Microscopy Laboratory

- A Dimension Icon Atomic Force Microscope (AFM)

- Wild Optical Macroscope-Stereo Microscope

- CCD camera for digital imaging Atomic Force Microscope (AFM)

- Leitz Mettallux Microscope

- Nikon UDM Eclipse LV1000 Optical Microscope

- Bruker D8 Discover 2 Dimension Wide Angle X-Ray

- SkyScan 1172: high resolution desktop micro-CT

Thermoplastic Processing Laboratory

- Twin Screw Haake Extruder

- Peltsman Low Pressure Injection Molder

- DACA Microextruder

- Q-U-V Accelerated Weathering Tester

- Perkin Elmer Series 2000 GPC Lab Scale Film Extrusion System

Impact Physics Laboratory

- Compression Split Hopkinson Pressure Bar

- Low Velocity Gas Gun

Autoclave Laboratory

- TEC – 1000°F, 515 psi Processing Autoclave

Non-Destructive Evaluation Laboratory

- Two 3x5ft water immersion ultrasonic tanks

Materials Interface Science Laboratory

- Dynamic Interphase Loading Apparatus (DILA)

- Microdroplet Tester

- Redlake High Speed Photography and Motion Analysis System

- Controlled-Atmosphere Microwave Furnace

- Hitachi TM 100 scanning Electron Microscope

- Instron 5848 Material Testing System

Applications and Technology Transfer Laboratory (ATTL)

- HPI 20 kip Pultrusion Machine

- Aqueous Bath Thermoplastic Prepreg Line

- Virtek Laser Projection System

- Spray Systems, Inc. Commercial Spray Booth, 34ft x 14ft x 12ft

- Entec Filament Winder

- Experimental Thermoplastic Lamination Workcell

- 3D Laser Scanner/Coordinate Measuring Machine

- HAAS VF-9/40 Vertical Machining Center

- MTS Servohydraulic System