Example 3:

Sphere Impact on Elliptical Carbon/Epoxy Tube

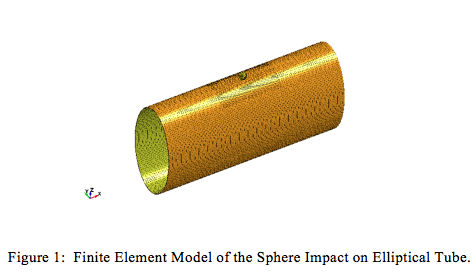

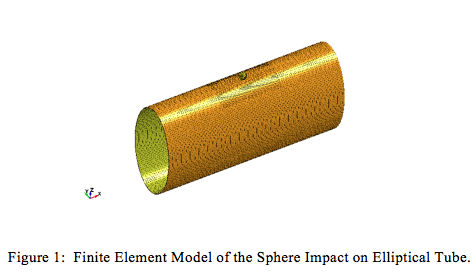

Impact on aircraft structure with curved surfaces require modeling with unidirectional carbon/epoxy composites. Materials Sciences Corporation has developed a set of carbon/epoxy unidirectional composites and are in the process of optimizing the MAT162 modeling parameters. In conducting parametric simulations an edge clamped elliptical tube of length 500mm and major and minor axis of 254mm and 152mm, respectively, has been meshed with 5mm mesh everywhere except at the impact point where the mesh size is 2.5mm. A steel sphere of 20mm diameter has been impacted with a velocity vector [Vx, Vy, Vz] = [+25, +25, -100] m/s. Four sub-laminates of thickness 0.500mm is stacked in the sequence [+45/-45/+45/-45] to obtain the total thickness of 2mm. Each sub-laminate has one element through the thickness and has been assigned an unique part number with respective material orientation in defining 3 potential delamination plane.

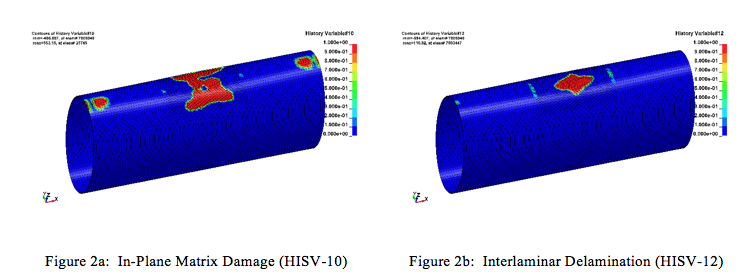

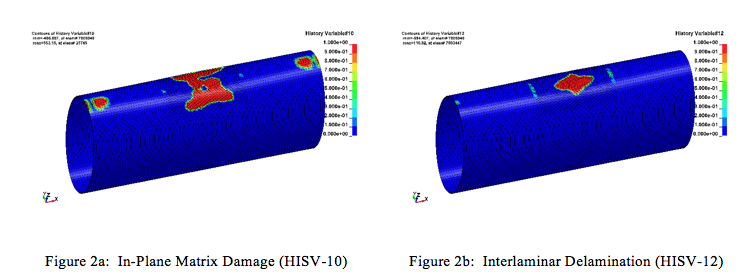

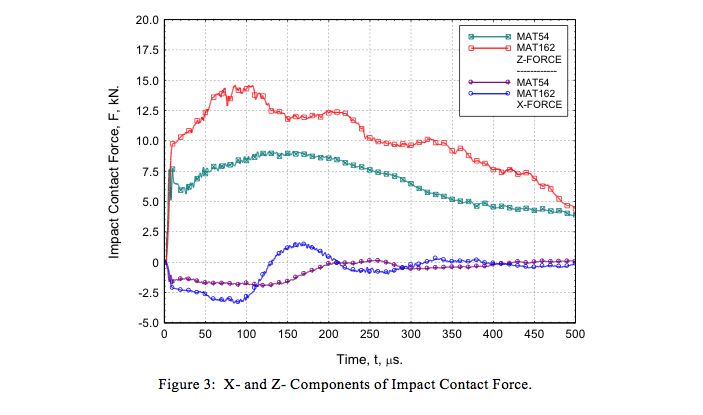

Figure 2 shows the in-plane matrix damage (2a) and interlaminar delamination (2b) at time t = 500 microseconds. MAT162 is a progressive composite damage model capable of predicting transverse matrix damage and delamination necessary to model composite damage. Results obtained from shell models will fail to model interlaminar delamination and predict a very different impact response. Figure 3 shows the MAT162 solid elements prediction of impact contact forces over a duration of 500 micro seconds along with the same for shell elements with MAT54. As expected, MAT54 predicts lower contact forces than MAT162 contact forces under identical initial loading and boundary conditions. Further parametric simulations will be conducted to optimize the MAT162 modeling parameters and compared with MAT54 predictions.

This example problem can be downloaded here.

| EXAMPLE 3: Sphere-Impact-on-Composite-TUBE.zip This zip folder contains the following KEWORD files. Run the first file. This zip folder contains the following KEWORD files. Run the first file. 001-mm-tonne-sec-INPUT-DECKS.key 002-CONTROL.key 003-elliptical-cylinder-SHELL-PART-100-SPC.key 003-elliptical-cylinder-SOLID-PART-101-to-104-FEM-SPC.key 004-700-Sphere-FEM.key 005-PARTS-700.key 005-PART-SETS.key 005-NODE-SETS.key 005-MAT162-Cards-for-T650-5250-5-UD-151-to-154.key 005-MAT54-Cards-for-T650-5250-5-UD-151-to-154.key 006-CONTACT-ERODING-SINGLE-SURFACE-SMP.key 007-DATABASE.key 007-DATABASE-CROSS-SECTION-PLANE.key 008-BOUNDARY-CONDITIONS.key 009-LOADING-CONDITIONS.key 010-INITIAL-CONDITIONS.key |