News

TuFF Material

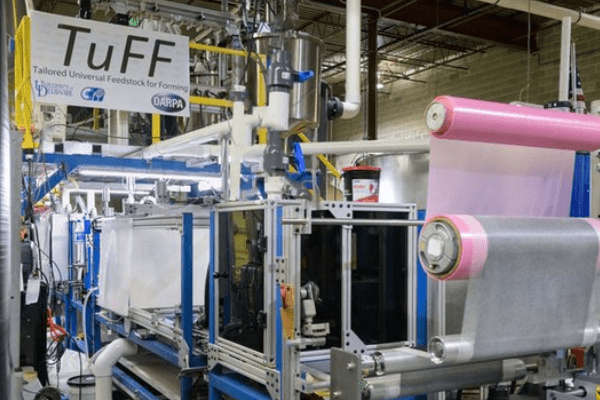

TuFF MaterialWorld’s strongest short fiber composite material for metal replacement achieves aerospace properties, metal-like formability in zero-waste, fiber-to-parts pilot plant.

TuFF Program Review Highly Successful

TuFF Program Review Highly SuccessfulOn June 13, 2017, TuFF partners met with DARPA and other government agencies for a highly successful program review.

The program is on schedule, with significant accomplishments demonstrating meeting/exceeding cost and performance targets of TuFF sheets.