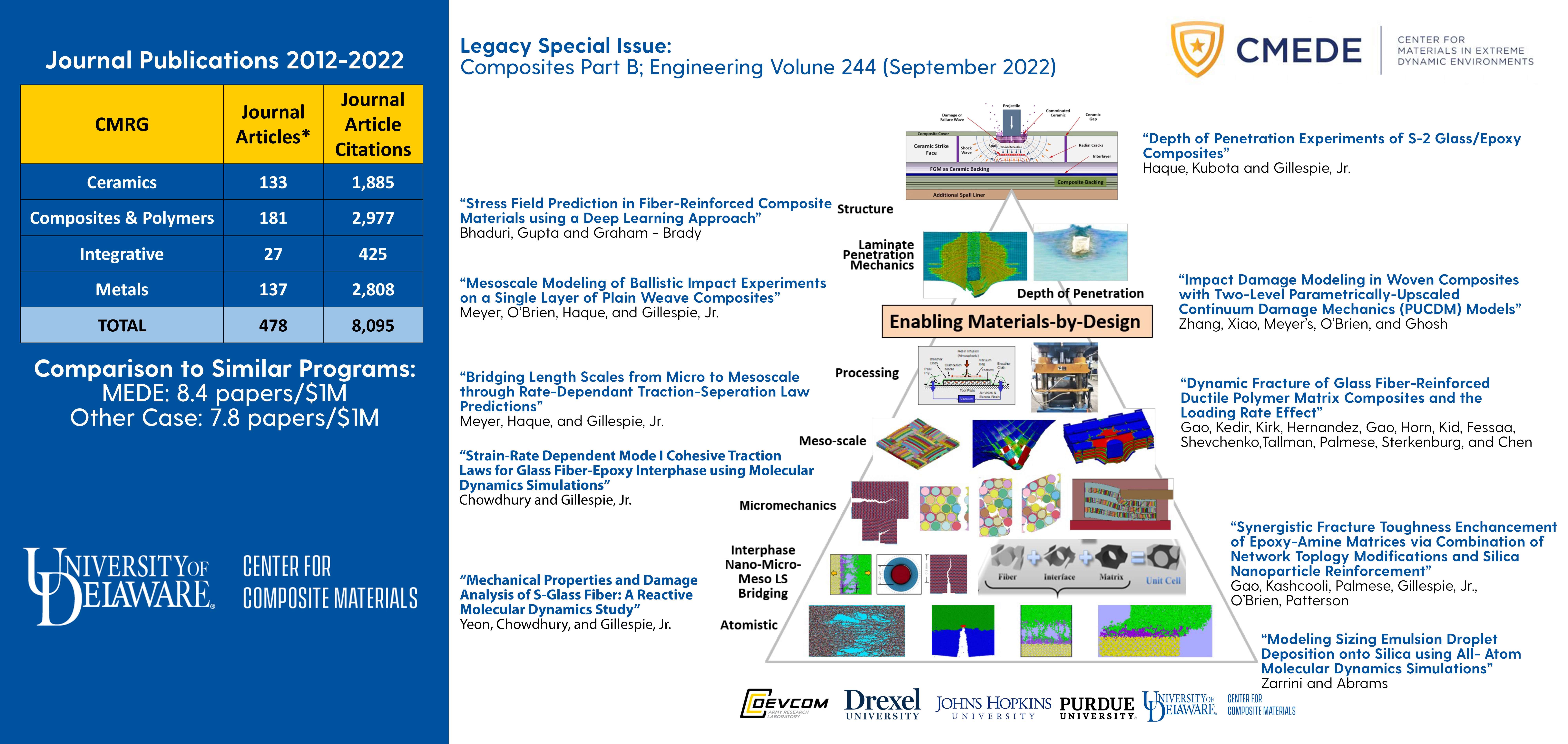

MEDE Publications

During the 10 year project (2012-2022) collaborators completed a combined total of 488 Journal Articles (Submitted, Accepted and Published). Below are the publications specific to UD-CCM researchers in the field of composites and polymers. Click HERE to download the full list of publications.

Legacy Articles

To provide a summative overview of research done by CMEDE, each research group collaborated on a special edition of journal.

Composites – Composites Part B: Engineering, Volume 244 (September 2022)

-

Bhaduri, Anindya, Gupta, Ashwini, Graham-Brady, Lori (2022) “Stress field prediction in fiber-reinforced composite materials using a deep learning approach.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109879.

-

Chowdhury, S.C., Gilliespie, Jr., J.W. (2021) “Strain-Rate Dependent Mode I Cohesive Traction Laws for Glass Fiber-Epoxy Interphase using Molecular Dynamics Simulations.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109877.

-

Gao, J. Kedir, N. Hernandez, J. Gao, J. Horn, T. Kim, G. Fezzaa, K. Tallman, T. Palmese, G. Sterkenburg, R. and Chen, W. (2021) “Dynamic fracture of glass fiber-reinforced ductile polymer matrix composites and loading rate effect.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109754.

-

Gao, J., Kashcooli, Y., Palmese., G., Gillespie, Jr., J.W., O’Brien, D., Patterson, B. (2021) “Synergistic Fracture Toughness Enhancement of Epoxy-Amine Matrices Via Combination of Network Topology Modification and Silica Nanoparticle Reinforcement.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109857.

-

Haque (Gama), B.Z., Kubota, M., Gillespie, Jr., J.W. (2022) “Depth of penetration experiments of S-2 glass/epoxy composites: A new Experimental Methodology in determining the rate dependent dynamic crush strength of composites.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109917.

-

Meyer, C.S., Haque, B.Z., Gillepsie, Jr., J.W. (2022) “Bridging Length Scales from Micro to Mesoscale through Rate-Dependent Traction-Seperation Law Predictions.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2021.109558.

-

Meyer, C., Haque (Gama), B.Z., O’Brien, D. (2022) “Mesoscale modeling of ballistic impact experiments on a single layer of plain weave composite.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109753.

-

Yeon, J., Chowdhury, S.C., Gillespie, Jr., J.W. (2022) “Mechanical Properties and Damage Analysis of S-glass Fiber: A Reactive Molecular Dynamics Study.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109706.

-

Zarrini, S., Abrams, C.F. (2022) “Modeling Sizing Emulsion Droplet Deposition Onto Silica Using All-Atom Molecular Dynamics Simulations.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109712.

-

Xiaofan Zhang, Yanrong Xiao, Christopher Meyer, Daniel O’Brien, Somnath Ghosh (2022) “Impact Damage Modeling in Woven Composites with Two-Level Parametrically-Upscaled Continuum Damage Mechanics Models (PUCDM).” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2021.109607.

Composites

2022

-

Ganesh, Raja, AbuObaid, A., Gillespie, Jr., J.W., “Novel Continuous Fiber Bending Experiment to Determine Size- and Spatial- Distributions of Surface Defects in Glass Fibers”, Composite Science and Technology, Submitted, October 2022

-

Ganesh, Raja, AbuObaid, A., Gillespie, Jr., J.W., “Experimental Determination of Bimodal Strength Distribution of S-Glass Fibers”, Composite Part B, Submitted, September 2022

-

Bhaduri, Anindya, Gupta, Ashwini, Graham-Brady, Lori (2022) “Stress field prediction in fiber-reinforced composite materials using a deep learning approach.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109879.

-

Haque (Gama), B.Z., Kubota, M., Gillespie, Jr., J.W. (2022) “Depth of penetration experiments of S-2 glass/epoxy composites: A new Experimental Methodology in determining the rate dependent dynamic crush strength of composites.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109917.

-

Meyer, C.S., Haque, B.Z., Gillepsie, Jr., J.W. (2022) “Bridging Length Scales from Micro to Mesoscale through Rate-Dependent Traction-Seperation Law Predictions.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2021.109558.

-

Meyer, C., Haque (Gama), B.Z., O’Brien, D. (2022) “Mesoscale modeling of ballistic impact experiments on a single layer of plain weave composite.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109753.

-

Yeon, J., Chowdhury, S.C., Gillespie, Jr., J.W. (2022) “Mechanical Properties and Damage Analysis of S-glass Fiber: A Reactive Molecular Dynamics Study.” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2022.109706.

-

Zarrini, S., Abrams, C.F. (2022) “Modeling Sizing Emulsion Droplet Deposition Onto Silica Using All-Atom Molecular Dynamics Simulations.” Composites Part B. doi: https://doi.org/10.1016/j.compositesb.2022.109712.

-

Xiaofan Zhang, Yanrong Xiao, Christopher Meyer, Daniel O’Brien, Somnath Ghosh (2022) “Impact Damage Modeling in Woven Composites with Two-Level Parametrically-Upscaled Continuum Damage Mechanics Models (PUCDM).” Composites Part B: Engineering, doi: https://doi.org/10.1016/j.compositesb.2021.109607.

2021

-

Bhaduri A., Meyer C.S., Gillespie J.W., Haque B.Z.G., Shields M.D., Graham-Brady L. (2021) “Probabilistic Modeling of Discrete Structural Response with Application to Composite Plate Penetration Models.” Journal of Engineering Mechanics, 147(11), doi: https://doi.org/10.1061/(ASCE)EM.1943-7889.0001996.

-

Bhaduri, A., Gupta, A., Graham-Brady, L. (2021) “Stress Field Prediction in Composite Materials Using Deep Learning.” Composites Part B.

-

Chowdhury, S.C., Gilliespie, Jr., J.W. (2021) “Strain-Rate Dependent Mode I Cohesive Traction Laws for Glass Fiber-Epoxy Interphase using Molecular Dynamics Simulations.” Composites Part B, doi: https://doi.org/10.1016/j.compositesb.2022.109877.

-

Gao, J. Fezzaa, K. and Chen, W. (2021) “Multiscale dynamic experiments on fiber-reinforced composites with damage assessment using high-speed synchrotron X-ray phase-contrast imaging.” NDT & E International, doi: https://doi.org/10.1016/j.ndteint.2022.102636

-

Gao, J. Guo, Z. Hernandez, J. Zhou, F. Nie, Y. Gao, J. Lim, B. Kedir, N. Zhai, X. Wang, J. Tsai, J. De Carlo, F. Shevchenko, P. Tallman, T. Jun, M.Palmese, G. and Chen, W. (2021) “Transverse Impact by RCCs on S-Glass and Kevlar® FRC Strips.” Composites Part A, 146(106425), doi: https://doi.org/10.1016/j.compositesa.2021.106425.

-

Gao, J. Kedir, N. Hernandez, J. Gao, J. Horn, T. Kim, G. Fezzaa, K. Tallman, T. Palmese, G. Sterkenburg, R. and Chen, W. (2021) “Dynamic fracture of glass fiber-reinforced ductile polymer matrix composites and loading rate effect.” Composites Part B: Engineering ,doi: https://doi.org/10.1016/j.compositesb.2022.109754.

-

Gao, J. Kedir, N. Kirk, C. Hernandez, J. Wang, J. Paulson, S. Zhai, X. Horn, T. Kim, G. Fezzaa, K. De Carlo, F. Shevchenko, P. Tallman, T. Sterkenburg, R. and Chen, W. (2021) “High-speed synchrotron X-ray phase-contrast imaging for evaluating microscale damage mechanisms and tracking cracking behaviors inside cross-ply GFRCs.” Composites Science and Technology, 210(108814), doi: https://doi.org/10.1016/j.compscitech.

-

Gao, J. Kedir, N. and Chen, W. (2021) “Characterization of failure of single carbon nanotube fibers under extreme transverse loading.” Journal of the Mechanics and Physics of Solids, doi: https://doi.org/10.1016/j.matdes.2022.110482

-

Gao, J., Kashcooli, Y., Palmese., G., Gillespie, Jr., J.W., O’Brien, D., Patterson, B. (2021) “Synergistic Fracture Toughness Enhancement of Epoxy-Amine Matrices Via Combination of Network Topology Modification and Silica Nanoparticle Reinforcement.” Composites Part B, doi: https://doi.org/10.1016/j.compositesb.2022.109857.

-

Haque, B. Z. and Gillespie, J. (2021) “Depth of Penetration of Dyneema HB26 Hard Ballistic Laminates.” Journal of Thermoplastic Composite Materials, doi: https://doi.org/10.1177/08927057211018532.

-

Kubota, M., Deitzel, J.M., Gillespie, Jr., J.W., Palmese, G.R., O’Brien, D. (2021) “Tailoring of Thin Silane Interphases in Glass/Epoxy Systems Through Vapor Deposition.” ASC Conference.

-

Meyer C.S., Bonyi E., Drake K., Obafemi-Babatunde T., Daodu A., Ajifa D., Bigio A., Taylor J., Haque B.Z., O’Brien D.J., Gillespie J.W., Aslan K. (2021) “Automated detection and quantification of transverse cracks on woven composites.” Journal of Reinforced Plastics and Composites, 40(23), 898-911. doi: https://doi.org/10.1177/07316844211017647.

-

Meyer, C.S., Catugas, I.G., Gillespie, Jr., J.W., Haque, B.Z. (2021) “Investigation of Normal, Lateral, and Oblique Impact of Microscale Projectiles into Unidirectional Glass/Epoxy Composites.” Defense Technology, doi: https://doi.org/10.1016/j.dt.2021.08.012.

-

Xiaofan Zhang, Yanrong Xiao, Christopher Meyer, Daniel O’Brien, Somnath Ghosh (2021) “Impact Damage Modeling in Woven Composites with Two-Level Parametrically-Upscaled Continuum Damage Mechanics Models (PUCDM).” Composites Part B: Engineering,doi: https://doi.org/10.1016/j.compositesb.2021.109607

-

Yeon, J. Chowdhury, S. C. Daksha, C. and Gillespie, J. (2021) “Development of Mg/Al/Si/O ReaxFF Parameters for Magnesium Aluminosilicate Glass using Artificial Neural Network Assisted Genetic Algorithm.” The Journal of Physical Chemistry, 125(33), 18380-18394. doi: https://doi.org/10.1021/acs.jpcc.1c01190.

-

Zarrini S., Abrams C.F. (2021) “Roles of the Coupling Agent and Surfactant in Droplet Structure in Sizing Emulsions: A Molecular Dynamics Simulations Study.” Langmuir, 37(33), 10183-10190. doi: https://doi.org/10.1021/acs.langmuir.1c01592.

2020

-

Bhaduri, A. Brandyberry, D. Shields, M. Geubelle, P. and Brady, L. (2020) “On the usefulness of gradient information in surrogate modeling: Application to uncertainty propagation in composite material models.” Probabilistic Engineering Mechanics, (60), doi: https://doi.org/10.1016/j.probengmech.2020.103024.

-

Bhaduri, A. Gardner, J. Abrams, C. and Brady, L. (2020) “Free energy calculation using space filled design and weighted reconstruction: A modified single sweep approach.” Molecular Simulations, 46(3), 193-206. doi: https://doi.org/10.1080/08927022.2019.1688325.

-

Chowdhury, S. C. Elder, R. Sirk, T. and Gillespie, J. (2020) “Epoxy resin thermo-mechanics and failure modes: Effects of cure and cross-linker length.” Composites Part B, 186, 107814-. doi: https://doi.org/10.1016/j.compositesb.2020.107814.

-

Chowdhury, S. C. Prosser, R. Sirk, T. Elder, R. and Gillespie, J. (2020) “Glass fiber-epoxy interactions in the presence of silane: A molecular dynamics study.” Applied Surface Science, 542, doi: https://doi.org/10.1016/j.apsusc.2020.148738.

-

Chu J.-M., Claus B., Lim B.H., O’Brien D., Sun T., Fezzaa K., Chen W. (2020) “Rate effects on fiber–matrix interfacial transverse debonding behavior.” Journal of Composite Materials, 54(4), 501-517. doi: https://doi.org/10.1177%2F0021998319866904.

-

Daksha, C. Yeon, J. Chowdhury, S. C. and Gillespie, J. (2020) “Automated ReaxFF Parametrization using Machine Learning.” Computational Materials Science Journal, 187, doi: https://doi.org/10.1016/j.commatsci.2020.110107.

-

Gao, J. Kedir, N. Kirk, C. Hernandez, J. Wang, J. Paulson, S. Zhai, X. Horn, T. Kim, G. Gao, J. Fezzaa, K. De Carlo, F. Shevchenko, P. Tallman, T. Sterkenburg, R. Palmese, G. and Chen, W. (2020) “Real-time damage characterization for GFRCs using high-speed synchrotron X-ray phase contrast imaging.” Composites Part B: Engineering, 207(108565), 1-14. doi: https://doi.org/10.1016/j.compositesb.2020.108565.

-

Gao, J. Kirk, C. Kedir, N. Paulson, S. Hernandez, J. Gao, J. Zhai, X. Wang, J. Horn, T. Kim, G. De Carlo, F. Shevchenko, P. Tallman, T. Palmese, G. Sterkenburg, R. and Chen, W. (2020) “A method for characterization of multiple dynamic constitutive parameters of FRCs.” Composites Science and Technology, 203(108607), 1-15. doi: https://doi.org/10.1016/j.compscitech.2020.108607.

-

Gao, J. Lim, B. Zhai, X. Kedir, N. and Chen, W. (2020) “Failure behaviors of single high-performance fibers under transverse dynamic cut.” 144,103660-. doi: https://doi.org/10.1016/j.ijimpeng.2020.103660.

2019

-

Bonyi, E. Meyer, C. Kioko, B. Adesina, O. Lansiquot, C. Onuk, Z. O’Brien, D. Haque, B. Z. Gillespie, J. and Aslan, K. (2019) “Assessment and quantification of ballistic impact damage of a single-layer woven fabric composite.” International Journal of Damage Mechanics, 28(2), 249-269. doi: https://doi.org/10.1177/1056789518758153.

-

Bonyi, E., Kioko, B., Meyer, C.S., Adesina, O., Obafami-Babatunde, T., Guy, J., O’Brien, D., Haque, B. Z., Gillespie, J.W., Aslan, K (2019) “Toward automated identification and quantification of meso-scale damage modes in plain weave glass/epoxy composite laminates.” International Journal of Damage Mechanics, 29(5), 831-848. doi: https://doi.org/10.1177/1056789519887215.

-

Chowdhury, S. C. Gillespie, J. and Sockalingam, S. (2019) “Inter-molecular interactions in ultrahigh molecular weight polyethylene single crystals.” Computational Materials Science, 172, 109360-. doi: https://doi.org/10.1016/j.commatsci.2019.109360.

-

Chowdhury, S. C. Wise, E. Ganesh, R. and Gillespie, J. (2019) “Effects of Surface Crack on the Mechanical Properties of Silica: A Molecular Dynamics Simulation Study.” Engineering Fracture Mechanics, 207(1), 99-108. doi: https://doi.org/10.1016/j.engfracmech.2018.12.025.

-

Haque, B. Z. Ali, M. Tamrakar, S. and Yen, C. O’Brien, D. Gillespie, J. Ganesh, R. and Yen, C. (2019) “Stochastic Micromechanical Modeling of Transverse Punch Shear Damage Behavior of Unidirectional Composites.” Journal of Composites Materials, 53(9), 1197-1213. doi: https://doi.org/10.1177/0021998318796174.

-

Li, Z. and Ghosh, S. (2019) “Developing Space-Time Boundary Conditions for Composite RVEs at High Strain-Rates.” International Journal of Solids and Structures, 166, 197-212. doi: https://doi.org/10.1016/j.ijsolstr.2019.02.019.

-

Li, Z. and Ghosh, S. (2019) “Micromechanics modeling and validation of thermal-mechanical damage in DER353 epoxy/borosilicate glass composite subject to high strain rate deformation.” International Journal of Impact Engineering, 136, Art. No. 103414–. doi: https://doi.org/10.1016/j.ijimpeng.2019.103414.

-

Sridhar, A. and Abrams, C. (2019) “Yield and Post-yield Behavior of Fatty-Acid-Functionalized Amidoamine–Epoxy Systems: A Molecular Simulation Study.” Journal of Dynamic Behavior of Materials, 5, 143-149. doi: https://doi.org/10.1007/s40870-019-00193-z.

-

Tamrakar, S. Ganesh, R. Haque, B. Z. and Gillespie, J. (2019) “Strain Rate Dependent Large Deformation Inelastic Behavior of An Epoxy Resin.” Journal of Composite Materials, doi: https://doi.org/10.1177/0021998319859054.

-

Tamrakar, S. Ganesh, R. Sockalingam, S. and Gillespie, J. (2019) “Rate dependent mode II traction separation law for S-2 glass/epoxy interface using a microdroplet test method.” Composites Part A: Applied Science and Manufacturing, 124, doi: https://doi.org/10.1016/j.compositesa.2019.105487.

-

Zhang, X. O’Brien, D. and Ghosh, S. (2019) “Parametrically Homogenized Continuum Damage Mechanics (PHCDM) Models for Composites from Micromechanical Analysis.” Computer Methods in Applied Mechanics and Engineering, 346, 456-485. doi: https://doi.org/10.1016/j.cma.2018.12.005.

2018

-

Abu-Obaid, A. and Gillespie, J. (2018) “Effects of abrasion on mechanical properties of Kevlar KM2-600 and S glass tows.” Textile Research Journal, 89, 989-1002. doi: https://doi.org/10.1177/0040517518760753.

-

An, Q. Tamrakar, S. Gillespie, J. Rider, A. and Thostenson, E. (2018) “Tailored Glass Fiber Interphases via Electrophoretic Deposition of Carbon Nanotubes: Fiber and Interphase Characterization.” Composite Science and Technology, 166, 131-139. doi: https://doi.org/10.1016/j.compscitech.2018.01.003.

-

Bhaduri, A. and Brady, L. (2018) “An efficient adaptive sparse grid collocation method through derivative estimation.” Probabilistic Engineering Mechanics, 51, 11-22. doi: https://doi.org/10.1016/j.probengmech.2017.11.002.

-

Bhaduri, A. He, Y. Shields, M. Graham-Brady, L. and Kirby, R. (2018) “Stochastic collocation approach with adaptive mesh refinement for parametric uncertainty analysis.” JOURNAL OF COMPUTATIONAL PHYSICS, 371, 732-750. doi: https://dx.doi.org/10.1016/j.jcp.2018.06.003.

-

Chowdhury, S. C. and Gillespie, J. (2018) “A molecular dynamics study of the effects of hydrogen bonds on mechanical properties of Kevlar® crystal.” Computational Material Science, 148(1), 286-300. doi: http://doi.org/10.1016/j.commatsci.2018.02.055.

-

Chowdhury, S. C. Wise, E. Ganesh, R. and Gillespie, J. (2018) “Effect of Surface Crack on the Mechanical Properties of Silica: A Molecular Dynamics Simulation Study.” Engineering Fracture Mechanics, 207, 99-107. doi: https://doi.org/10.1016/j.engfracmech.2018.12.025.

-

Chu, J. Claus, B. Parab, N. O’Brien, D. Sun, T. Fezzaa, K. and Chen, W. (2018) “Visualization of dynamic fiber-matrix interfacial shear debonding.” Journal of Materials Science, 53(8), 5845-5859. doi: https://doi.org/10.1007/s10853-017-1759-1.

-

Ganesh, R. Sockalingam, S. and Gillespie, J. (2018) “Dynamic effects of a single fiber break in unidirectional glass fiber-reinforced polymer composites: Effects of matrix plasticity.” Journal of Composite Materials, 52(14), 1873-1886. doi: http://doi.org/10.1177/0021998317737604.

-

Meyer, C. Bonyi, E. Haque, B. Z. O’Brien, D. Aslan, K. and Gillespie, J. (2018) “Ballistic Impact Experiments and Quantitative Assessments of Mesoscale Damage Modes in a Single-Layer Woven Composite.” Dynamic Behavior of Materials, 1, 9-17. doi: https://doi.org/10.1007/978-3-319-95089-1_2.

-

Meyer, C. Haque, B. Z. O’Brien, D. Getinet, N. Yu, J. Bonyi, E. Aslan, K. and Gillespie, J. (2018) “Mesoscale Ballistic Damage Mechanics of a Single-Ply Woven Glass/Epoxy Composite.” International Journal of Impact Engineering, 113(1), 118-131. doi: https://doi.org/10.1016/j.ijimpeng.2017.11.005.

-

Nie, Y. Parab , N. Chu, J. Kim, G. Sun, T. Fezzaa, K. Sterkenburg, R. and Chen, W. (2018) “Dynamic Crack Propagation from a Circular Defect in a Unidirectional CFRP Composite.” Journal of Composite Materials, 52(25), 3539-3547. doi: https://doi.org/10.1177/0021998318797394.

-

Srikanth, A. Kinaci, E. Vergara, J. Palmese, G. and Abrams, C. (2018) “The effect of alkyl chain length on mechanical properties of fatty-acid-functionalized amidoamine-epoxy systems.” Computational Materials Science, 150, 70-76. doi: https://doi.org/10.1016/j.commatsci.2018.03.073.

-

Tamrakar, S. Ganesh, R. Sockalingam, S. Haque, B. Z. and Gillespie, J. (2018) “Experimental Investigation of Strain Rate and Temperature Dependent Response of an Epoxy Resin Undergoing Large Deformation.” Journal of Dynamic Behavior of Materials, 4(1), 114-128. doi: https://doi.org/10.1007/s40870-018-0144-8.

-

Yeon, J. Chowdhury, S. C. Mrityunjay, D. and Gillespie, J. (2018) “Atomistic scale simulation for the inter-diffusion of Epoxy-Amine.” ASC 33rd Technical Conference, doi: https://doi.org/10.12783/asc33/25918.

2017

-

Chen, W. Hudspeth, M. Guo, Z. Lim, B. Horner, S. and Zheng, J. (2017) “Multi-scale experiments on soft body armors under projectile normal impact. “International Journal of Impact Engineering, 108, 63-72. doi: https://doi.org/10.1016/j.ijimpeng.2017.04.018.

-

Chowdhury, S. C. and Gillespie, J. (2017) “Silica – silane coupling agent interphase properties using molecular dynamics simulations.” Journal of Materials Science, 52, 12981-12988. doi: https://doi.org/10.1007/s10853-017-1412-z.

-

Chowdhury, S. C. Elder, R. Sirk, T. van Duin, A. and Gillespie, J. (2017) “Modeling of glycidoxypropyltrimethoxy silane compositions using molecular dynamics simulations.” Computational Materials Science, 140, 82-88. doi: http://dx.doi.org/10.1016/j.commatsci.2017.08.033.

-

Ganesh, R. Sockalingam, S. Haque, B. Z. and Gillespie, J. (2017) “Dynamic effects of single fiber break in unidirectional glass fiber-reinforced composites.” Journal of Composite Materials, 51(9), 1307-1320. doi: http://dx.doi.org/10.1177/0021998316669218.

-

Srikanth, A. Vergara, J. Palmese, G. and Abrams, C. (2017) “The effect of alkyl chain length on material properties of fatty-acid-functionalized amidoamine-epoxy systems.” European Polymer Journal, 89, 1-12. doi: https://doi.org/10.1016/j.eurpolymj.2017.01.037.

-

Tamrakar, S. Ganesh, R. Sockalingam, S. Haque, B. Z. and Gillespie, J. (2017) “Thermo-mechanical response of epoxy resin at different rates of loading.” Materials and Design.

-

Yang, J. Srikanth, A. Jang, C. and Abrams, C. (2017) “Relationships between molecular structure and thermomechanical properties of bio-based thermosetting polymers.” Journal of Polymer Science, Part B: Polymer Physics, 55, 285-292. doi: https://doi.org/10.1002/polb.24270.

-

Yeager, M. Simacek, P. and Advani, S. (2017) “Role of fiber distribution and air evacuation time on capillary driven flow into fiber tows.” Composites Part A: Applied Science and Manufacturing, 93, 144-152. doi: https://doi.org/10.1016/j.compositesa.2016.11.016.

2016

-

Bain, E. Knorr, D. Richardson, A. Masser, K. Yu, J. and Lenhart, J. (2016) “Failure processes governing high-rate impact resistance of epoxy resins filled with core–shell rubber nanoparticles.” Journal of Materials Science, 51(5), 2347-2370. doi: http://dx.doi.org/10.1007/s10853-015-9544-5.

-

Chen, W. (2016) “Experimental Methods for Characterizing Dynamic Response of Soft Materials.” Journal of Dynamic Behavior of Materials, 2(1), 2-14. doi: https://doi.org/10.1007/s40870-016-0047-5.

-

Chowdhury, S. C. Haque, B. Z. and Gillespie, J. (2016) “Molecular dynamics simulations of the structure and mechanical properties of silica glass using ReaxFF.” Journal of Materials Science, 51(22), 10139-10159. doi: https://link.springer.com/article/10.1007/s10853-016-0242-8.

-

Grujicic, M. Ramaswami, S. Snipes, J. Avuthu, V. Yen, C. and Cheeseman, B. (2016) “Application of the materials-by-design approach to armor-grade polymer-matrix composites for enhancement of ballistic-penetration resistance.” International Journal of Structural Integrity, 7(1), 142-174. doi: http://dx.doi.org/10.1108/IJSI-02-2015-0005.

-

Guo, S. Casem, D. Hudspeth, M. Farbaniec, L. Sun, J. and Chen, W. (2016) “Transverse compression of two high-performance ballistic fibers.” Textile Research Journal, 86(5), 502-511. doi: http://dx.doi.org/10.1177/0040517515592814.

-

Haque, B. Z. Chowdhury, S. C. and Gillespie, J. (2016) “Molecular Simulations of Stress Wave Propagation and Perforation of Graphene Sheets under Transverse Impact.” Carbon, 102, 126-140. doi: https://doi.org/10.1016/j.carbon.2016.02.033.

-

Jang, C. and Abrams, C. (2016) “Thermal and mechanical properties of thermosetting polymers using coarse-grained simulation.” The European Physical Journal Special Topics, 225, 1775-1783. doi: https://doi.org/10.1140/epjst/e2016-60143-0.

-

Jang, C. Sharifi, M. Palmese, G. and Abrams, C. (2016) “Toughness enhancement of thermosetting polymers using a novel partially reacted substructure curing protocol: A combined molecular simulation and experimental study.” Polymer, 90, 249-255. doi: https://doi.org/10.1016/j.polymer.2016.03.023.

-

Levine, S. Nie, Y. and Chen, W. (2016) “Dynamic Transverse Debonding of a Single Fiber.” Journal of Dynamic Behavior of Materials, 2(4), 521-531. doi: https://link.springer.com/article/10.1007/s40870-016-0086-y.

-

Li, Z. Ghosh, S. Getinet, N. and O’Brien, D. (2016) “Micromechanical modeling and characterization of damage evolution in glass fiber epoxy matrix composites.” Mechanics of Materials, 99, 37-52. doi: https://doi.org/10.1016/j.mechmat.2016.05.006.

-

Masser, K. Bain, E. Beyer, F. Savage, A. Yu, J. and Lenhart, J. (2016) “Influence of nano-scale morphology on impact toughness of epoxy blends.” Polymer, 103, 337-346. doi: https://doi.org/10.1016/j.polymer.2016.09.076.

-

Misumi, J. Ganesh, R. Sockalingam, S. and Gillespie, J. (2016) “Experimental characterization of tensile properties of epoxy resin by using micro-fiber specimens.” Journal of Reinforced Plastics and Composites, 35(24), 1792-1801. doi: http://dx.doi.org/10.1177/0731684416669248.

-

Sun, J. Hudspeth, M. and Chen, W. (2016) “Biaxial Shear/Tension Failure Behavior of Spectra Single Fibers.” Composites Part A: Applied Science and Manufacturing, 88, 286-294. doi: https://doi.org/10.1016/j.compositesa.2016.06.009.

-

Tamrakar, S. An, Q. Thostenson, E. Rider, A. and Gillespie, J. (2016) “Tailoring Interfacial Properties by Controlling Carbon Nanotube Coating Thickness on Glass Fibers Using Electrophoretic Deposition.” ACS Applied Materials & Interfaces, 8(2), 1501-1510. doi: http://dx.doi.org/10.1021/acsami.5b10903.

-

Tamrakar, S. Haque, B. Z. and Gillespie, J. (2016) “High rate test method for fiber-matrix interface characterization.” Polymer Testing, 52, 174-183. doi: http://dx.doi.org/10.1016/j.polymertesting.2016.04.016.

-

Yeager, M. Hwang, W. and Advani, S. (2016) “Prediction of capillary pressure for resin flow between fibers.” Composites Science and Technology, 126, 130-138. doi: https://doi.org/10.1016/j.compscitech.2016.02.014.

2015

-

Elder, R. Andzelm, J. and Sirk, T. (2015) “A molecular simulation study of the glass transition of cross-linked poly(dicyclopentadiene) networks.” Chemical Physics Letters, 637, 103-109. doi: https://doi.org/10.1016/j.cplett.2015.07.058.

-

Gao, H. Gillespie, J. Jensen, R. Li, W. Haque, B. Z. and McKnight, S. (2015) “Effect of fiber surface texture on the mechanical properties of glass fiber reinforced epoxy composite.” Composites Part A: Applied Science and Manufacturing, 74, 10-17. doi: https://doi.org/10.1016/j.compositesa.2015.03.023.

-

Ghosh, S. (2015) “Foundational aspects of a multi-scale modeling framework for composite materials.” Integrating Materials and Manufacturing Innovation, 4(9), 1-28. doi: http://dx.doi.org/10.1186/s40192-015-0036-x.

-

Haque, B. Z. and Gillespie, J. (2015) “A new penetration equation for ballistic limit analysis.” Journal of Thermoplastic Composite Materials, 28(7), 950-972. doi: http://dx.doi.org/10.1177/0892705713495430.

-

Haque, B. Z. and Gillespie, J. (2015) “Penetration and Perforation of Composite Structures.” Mechanical Engineering Research Journal, 9, 37-42. doi: http://www.cuet.ac.bd/merj/files/MERJ-Vol-9,%202013,%20page%2037-42.pdf.

-

Hudspeth, M. Claus, B. Parab, N. Lim, B. Sun, T. Fezza, K. and Chen, W. (2015) “In Situ Visual Observation of Fracture Processes in Several High-Performance Fibers.” Journal of Dynamic Behavior of Materials, 1(1), 55-64. doi: http://dx.doi.org/10.1007/s40870-015-0009-3.

-

Jang, C. Sirk, T. Andzelm, J. and Abrams, C. (2015) “Comparison of Crosslinking Algorithms in Molecular Dynamics Simulation of Thermosetting Polymers.” Macromolecular Theory and Simulations, 24, 260-270. doi: https://doi.org/10.1002/mats.201400094.

-

Karkkainen, R. (2015) “Dynamic micromechanical modeling of textile composite strength under impact and multi-axial loading.” Composites Part B: Engineering, 83, 27-35. doi: https://doi.org/10.1016/j.compositesb.2015.08.009.

-

Knorr, D. Masser, K. Elder, R. Sirk, T. Hindenlang, M. Yu, J. Richardson, A. Boyd, S. Spurgeon, W. and Lenhart, J. (2015) “Overcoming the structural versus energy dissipation trade-off in highly crosslinked polymer networks: Ultrahigh strain rate response in polydicyclopentadiene.” Composites Science and Technology, 114, 17-25. doi: https://doi.org/10.1016/j.compscitech.2015.03.021.

-

Masser, K. Knorr, D. Hindenlang, M. Yu, J. Richardson, A. Strawhecker, K. Beyer, F. and Lenhart, J. (2015) “Relating structure and chain dynamics to ballistic performance in transparent epoxy networks exhibiting nanometer scale heterogeneity.” Polymer, 58, 96-106. doi: https://doi.org/10.1016/j.polymer.2014.12.027.

-

Mc Aninch, I. Palmese, G. Lenhart, J. and La Scala, J. (2015) “Epoxy-amine networks with varying epoxy polydispersity.” Journal of Applied Polymer Science, 132(8), 1097-4628. doi: http://dx.doi.org/10.1002/app.41503.

-

Sharifi, M. Jang, C. Abrams, C. and Palmese, G. (2015) “Epoxy Polymer Networks with Improved Thermal and Mechanical Properties via Controlled Dispersion of Reactive Toughening Agents.” Macromolecules, 48(20), 7495-7502. doi: http://dx.doi.org/10.1021/acs.macromol.5b00677.

-

Yeager, M. and Advani, S. (2015) “Numerical model of fiber wetting with finite resin volume.” Integrating Materials and Manufacturing Innovation, 4(3), 1-16. doi: http://dx.doi.org/10.1186/s40192-015-0032-1.

2014

-

Dey, M. Deitzel, J. Gillespie, J. and Schweiger, S. (2014) “Influence of sizing formulations on glass/epoxy interphase properties.” Composites Part A: Applied Science and Manufacturing, 63, 59-67. doi: http://dx.doi.org/10.1016/j.compositesa.2014.04.006.

-

Jang, C. Sharifi, M. Palmese, G. and Abrams, C. (2014) “Crosslink network rearrangement via reactive encapsulation of solvent in epoxy curing: A combined molecular simulation and experimental study.” Polymer, 55(16), 3859-3868. doi: http://dx.doi.org/10.1016/j.polymer.2014.06.022.

-

Sharifi, M. Jang, C. Abrams, C. and Palmese, G. (2014) “Toughened epoxy polymers via rearrangement of network topology.” J. Mater. Chem. A, 2, 16071-16082. doi: http://dx.doi.org/10.1039/C4TA03051F.

-

Sockalingam, S. Gillespie, J. and Keefe, M. (2014) “On the transverse compression response of Kevlar KM2 using fiber-level finite element model.” International Journal of Solids and Structures, 51(13), 2504-2517. doi: https://doi.org/10.1016/j.ijsolstr.2014.03.020.

-

Sockalingam, S. Mody, P. Gillespie, J. and Keefe, M. (2014) “Finite element analysis of the microdroplet test method using cohesive zone model of the fiber/matrix interface.” Composites Part A: Applied Science and Manufacturing, 56, 239-247. doi: https://doi.org/10.1016/j.compositesa.2013.10.021.

2013

-

Bogetti, T. Staniszewski, J. Burkins, M. Hoppel, C. Gillespie, J. and Tamrakar, S. (2013) “Predicting the nonlinear response and progressive failure of composite laminates under triaxial loading: Correlation with experimental results.” Journal of Composite Materials, 47, 793-804. doi: http://dx.doi.org/10.1177/0021998312462616.

-

McAninch, I. Palmese, G. Lenhart, J. and Lascala, J. (2013) “Characterization of epoxies cured with bimodal blends of polyetheramines.” Journal of Applied Polymer Science, 130(3), 1621-1631. doi: http://dx.doi.org/10.1002/app.39322.

2012

-

Bogetti, T. Staniszewski, J. Burns, B. Hoppel, C. Gillespie, J. and Tierney, J. (2012) “Predicting the nonlinear response and progressive failure of composite laminates under tri-axial loading.” Journal of Composite Materials, 46(19), 2443-2459. doi: https://doi.org/10.1177/0021998312449889.

-

Haque, B. Z. and Gillespie, J. (2012) “A Quasi-Static Penetration Model of Ballistic Penetration of Thick-Section Composites.” Failure in Composites, 4, doi: https://www.researchgate.net/publication/286697762_A_quasi-static_penetration_model_of_ballistic_penetration_of_thick-section_composites.

-

Haque, B. Z. and Gillespie, J. (2012) “A combined theoretical-semiempirical penetration model of ballistic penetration of thick section composites.” Journal of Thermoplastic Composite Materials, 25(5), 631-659. doi: http://dx.doi.org/10.1177/0892705712450296.

-

Haque, B. Z. Harrington, J. and Gillespie, J. (2012) “Multi-hit ballistic impact on S-2 glass/SC15 thick-section composites: finite element analyses.” The Journal of Strain Analysis for Engineering Design, 47(7), 495-512. doi: http://dx.doi.org/10.1177/0309324712456823.

-

Karkkainen, R. and McWilliams, B. (2012) “Dynamic micromechanical modeling of textile composites with cohesive interface failure.” Journal of Composite Materials, 46(18), 2203-2218. doi: https://doi.org/10.1177/0021998311430544.

-

Karkkainen, R. and Yen, C. (2012) “Dynamic modeling for rate-dependent and mode-dependent cohesive interface failure analysis.” Journal of Composite Materials, 46(18), 2193-2201. doi: https://doi.org/10.1177/0021998311430543.

-

Lopatnikov, S. Shevchenko, N. and Gillespie, J. (2012) “Device and Method for Investigation of Mechanical Properties of Fibers under High-Strain Rate Tensile Load.” Cornell University Library, 1, 1-6. doi: https://arxiv.org/pdf/1201.0916.pdf.

Polymers

2021

-

Haque, B.Z., Gillespie, Jr., J.W. (2021) “Perforation Mechanics of UHMWPE Soft Ballistic Sub-Laminate and Soft Ballistic Armor Pack: A Finite Element Study.” Journal of Thermoplastic Composites, doi: https://doi.org/10.1177/08927057211042058.

2020

-

O’Connor T.C., Robbins M.O. (2020) “Molecular models for creep in oriented polyethylene fibers.” Journal of Chemical Physics, 153(14), doi: https://doi.org/10.1063/5.0021286.

2019

-

Abu-Obaid, A. Ganesh, R. and Gillespie, J. (2019) “Investigation of Axial Compressive Behavior of Kevlar Fibers Using Dynamic Loop Test.” Textile Research Journal, 1-14. doi: https://doi.org/10.1177/0040517518821898.

-

Galvani Cunha, M. and Robbins, M. O. (2019) “Determination of pressure-viscosity relation of 2,2,4-trimethylhexane by all-atom molecular dynamics simulations.” Fluid Phase Equilib.,, 495, 28-32. doi: https://doi.org/10.1016/j.fluid.2019.05.008.

-

Jadhao, V. and Robbins, M. O. (2019) “Rheological Properties of Liquids Under Conditions of Elastohydrodynamic Lubrication.” Tribology Letters, 67, doi: https://doi.org/10.1007/s11249-019-1178-3.

-

O’connor T.C., Hopkins A., Robbins M.O. (2019) “Stress Relaxation in Highly Oriented Melts of Entangled Polymers.” Macromolecules, 52(22), 8540-8550. doi: https://doi.org/10.1021/acs.macromol.9b01161.

2018

-

Dong, H. Wang, Z. O’Connor, T. C. Azoug, A. Robbins, M. O. and Nguyen, T. (2018) “Micromechanical models for the stiffness and strength of {UHMWPE} macrofibrils.” Journal of the Mechanics and Physics of Solids, 116, 70-98. doi: https://doi.org/10.1016/j.jmps.2018.03.015.

-

McDaniel, P. Deitzel, J. Gillespie, J. and Strawhecker, K. (2018) “Nanoscale Interfibrillar Adhesion in UHMWPE Fibers.” Journal of Polymer Science Part B: Polymer Physics, 56(5), 391-401. doi: https://doi.org/10.1002/polb.24552.

-

O’Connor, T. Alvarez, N. and Robbins, M. O. (2018) “Relating Chain Conformations to Extensional Stress in Entangled Polymer Melts.” Phys. Rev. Lett., 121(4), doi: http://doi.org/10.1103/PhysRevLett.121.047801.

-

O’Connor, T. Elder, R. Sliozberg, Y. Sirk, T. Andzelm, J. and Robbins, M. O. (2018) “Molecular origins of anisotropic shock propagation in crystalline and amorphous polyethylene.” Phys. Rev. Materials, 2(3), doi: https://doi.org/10.1103/PhysRevMaterials.2.035601.

-

Polakovic, T. Gregory, D. McDaniel, P. Deitzel, J. and Gillespie, J. (2018) “A Single Fiber Peel Test to Assess Ultra High Molecular Weight Polyethylene Fiber Mesostructured Interactions.” Journal of Applied Polymer Science, 135(16), 46-156. doi: https://doi.org/10.1002/app.46156.

-

Sockalingam, S. Thomas, F. Casem, D. Gillespie, J. and Weerasooriya, T. (2018) “Failure of Dyneema® SK76 single fiber under multiaxial transverse loading.” Textile Research Journal, 89(13), 2659-2673. doi: https://doi.org/10.1177/0040517518798653.

-

Staniszewski, J. Sockalingam, S. Bogetti, T. and Gillespie, J. (2018) “Modeling the Fibrillation of Kevlar KM2 Single Fibers Subjected to Transverse Compression.” Fibers and Polymers, 19(7), 1479-1489. doi: https://doi.org/10.1007/s12221-018-8127-x.

2017

-

Bogetti, T. Walter, M. Staniszewski, J. and Cline, J. (2017) “Interlaminar shear characterization of ultra-high molecular weight polyethylene (UHMWPE) composite laminates.” Composites Part A: Applied Science and Manufacturing, 98, 105-115. doi: https://doi.org/10.1016/j.compositesa.2017.03.018.

-

Brayton, A. Yeh, I. Andzelm, J. and Rutledge, G. (2017) “Vibrational Analysis of Semicrystalline Polyethylene Using Molecular Dynamics Simulation.” Macromolecules, 50(17), 6690-6701. doi: https://dx.doi.org/10.1021/acs.macromol.7b00995.

-

Chowdhury, S. C. Sockalingam, S. and Gillespie, J. (2017) “Molecular Dynamics Modeling of the Effect of Axial and Transverse Compression on the Residual Tensile Properties of Ballistic Fiber.” Fibers, 5(7), 1-16. doi: http://www.mdpi.com/2079-6439/5/1/7/htm.

-

Deitzel, J. McDaniel, P. and Gillespie, J. (2017) “Chapter 10: High Performance Polyethylene Fibers.” Structure and Properties of High-Performance Fibers, 1(1), 167-185. doi: https://doi.org/10.1016/B978-0-08-100550-7.00007-3.

-

Elder, R. O’Connor, T. C. Chantawansri, T. Sliozberg, Y. Sirk, T. Yeh, I. Robbins, M. O. and Andzelm, J. (2017) “Shock-wave propagation and reflection in semicrystalline polyethylene: A molecular-level investigation.” Phys. Rev. Materials, 1, 43606-43606. doi: http://dx.doi.org/10.1103/PhysRevMaterials.1.043606.

-

Haque, B. Z. Ali, M. and Gillespie, J. (2017) “Modeling Transverse Impact on UHMWPE Soft Ballistic Sub-Laminate.” Journal of Thermoplastic Composite Materials, 30(11), 1441-1483. doi: https://doi.org/10.1177/0892705716637114.

-

Jadhao, V. and Robbins, M. O. (2017) “Correction for Jadhao and Robbins, Probing large viscosities in glass-formers with nonequilibrium simulations.” Proceedings of the National Academy of Sciences, 114(39), 8317-8317. doi: https://doi.org/10.1073/pnas.1715376114.

-

Jadhao, V. and Robbins, M. O. (2017) “Probing large viscosities in glass-formers with nonequilibrium simulations.” Proceedings of the National Academy of Sciences, 114(30), 7952-7957. doi: http://dx.doi.org/10.1073/pnas.1705978114.

-

Jadhao, V. and Robbins, M. O. (2017) “Reply to Bair: Crossover to Arrhenius behavior at high viscosities in squalane.” Proceedings of the National Academy of Sciences, 114(42), 8807-8808. doi: http://dx.doi.org/10.1073/pnas.1715298114.

-

McDaniel, P. Deitzel, J. Gillespie, J. and Strawhecker, K. (2017) “Influence of sub-filament structure on failure mechanisms for mode I and II loading conditions in UHMWPE filaments.”

-

McDaniel, P. Deitzel, J. Gillespie, J. and Strawhecker, K. (2017) “Measurement of Microfibril Adhesion in UHMW PE fibers through Nanomechanical testing.”

-

McDaniel, P. Sockalingam, S. Deitzel, J. Gillespie, J. Keefe, M. Bogetti, T. Casem, D. and Weerasooriya, T. (2017) “The effect of fiber meso/nanostructure on the transverse compression response of ballistic fibers.” Composites Part A: Applied Science and Manufacturing, 94, 133-145. doi: https://doi.org/10.1016/j.compositesa.2016.12.003.

-

Sockalingam, S. Casem, D. Weerasooriya, T. McDaniel, P. and Gillespie, J. (2017) “Experimental Investigation of the High Strain Rate Transverse Compression Behavior of Ballistic Single Fibers.” Journal of Dynamic Behavior of Materials, 3(3), 474-484. doi: http://dx.doi.org/10.1007/s40870-017-0126-2.

-

Sockalingam, S. Chowdhury, S. C. Gillespie, J. and Keefe, M. (2017) “Recent Advances in Modeling and Experiments of Kevlar Ballistic Fibrils, Fibers, Yarns and Flexible Textile Fabrics – A Review.” Textile Research Journal, 87(8), 984-1010. doi: https://doi.org/10.1177/0040517516646039.

-

Sockalingam, S. Gillespie, J. and Keefe, M. (2017) “Modeling the Fiber Length- Scale Response of Kevlar KM2 Yarn During Transverse Impact.” Textile Research Journal, 87(8), 2242-2254. doi: https://doi.org/10.1177/0040517516669074.

-

Sockalingam, S. Gillespie, J. and Keefe, M. (2017) “Role of Inelastic Transverse Compressive Behavior and Multiaxial Loading on the Transverse Impact of Kevlar KM2 Single Fiber.” Fibers, 5(1), 1-9. doi: http://dx.doi.org/10.3390/fib5010009.

-

Yeh, I. Lenhart, J. Rutledge, G. and Andzelm, J. (2017) “Molecular Dynamics Simulation of the Effects of Layer Thickness and Chain Tilt on Tensile Deformation Mechanisms of Semicrystalline Polyethylene.” Macromolecules, 50(4), 1700-1712. doi: http://dx.doi.org/10.1021/acs.macromol.6b01748.

2016

-

Elder, R. Knorr, D. Andzelm, J. Lenhart, J. and Sirk, T. (2016) “Nanovoid formation and mechanics: a comparison of poly(dicyclopentadiene) and epoxy networks from molecular dynamics simulations.” Soft Matter, 12, 4418-4434. doi: http://dx.doi.org/10.1039/C6SM00691D.

-

Hsieh, A. Chantawansri, T. Hu, W. Cain, J. and Yu, J. (2016) “New insight into the influence of molecular dynamics of matrix elastomers on ballistic impact deformation in UHMWPE composites.” Polymer, 95, 52-61. doi: https://doi.org/10.1016/j.polymer.2016.04.048.

-

O’Connor, T. C. and Robbins, M. O. (2016) “Chain Ends and the Ultimate Strength of Polyethylene Fibers.” ACS Macro Letters, 5(3), 263-267. doi: http://dx.doi.org/10.1021/acsmacrolett.5b00838.

-

Obaid, A. Yarlagadda, S. and Gillespie, J. (2016) “Combined effects of kink bands and hygrothermal conditioning on tensile strength of polyarylate liquid crystal co-polymer and aramid fibers.” Journal of Composite Materials, 50(3), 339-350. doi: http://dx.doi.org/10.1177/0021998315574754.

-

Sliozberg, Y. Kröger, M. and Chantawansri, T. (2016) “Fast equilibration protocol for million atom systems of highly entangled linear polyethylene chains.” The Journal of Chemical Physics, 144(15), 154-901. doi: http://dx.doi.org/10.1063/1.4946802.

-

Sockalingam, S. Bremble, R. Gillespie, J. and Keefe, M. (2016) “Transverse compression behavior of Kevlar KM2 single fiber.” Composites Part A: Applied Science and Manufacturing, 81, 271-281. doi: https://doi.org/10.1016/j.compositesa.2015.11.032.

-

Sockalingam, S. Gillespie, J. and Keefe, M. (2016) “Influence of multiaxial loading on the failure of Kevlar KM2 single fiber.” Textile Research Journal, 88(5), 483-498. doi: http://dx.doi.org/10.1177/0040517516681961.

-

Veysset, D. Hsieh, A. Kooi, S. Maznev, A. Masser, K. and Nelson, K. (2016) “Dynamics of supersonic microparticle impact on elastomers revealed by real–time multi–frame imaging.” Scientific Reports, 6, 25577-25577. doi: http://doi.org/10.1038/srep25577.

-

Wang, Y. Miao, Y. Huang, L. Swenson, D. Yen, C. Yu, J. and Zheng, J. (2016) “Effect of the inter-fiber friction on fiber damage propagation and ballistic limit of 2-D woven fabrics under a fully confined boundary condition.” International Journal of Impact Engineering, 97, 66-78. doi: https://doi.org/10.1016/j.ijimpeng.2016.06.007.

2015

-

Chantawansri, T. Yeh, I. and Hsieh, A. (2015) “Investigating the glass transition temperature at the atom-level in select model polyamides: A molecular dynamics study.” Polymer, 81, 50-61. doi: https://doi.org/10.1016/j.polymer.2015.09.069.

-

McDaniel, P. Deitzel, J. and Gillespie, J. (2015) “Structural Hierarchy and Surface Morphology of Highly Drawn Ultra High Molecular Weight Polyethylene Fibers Studied by Atomic Force Microscopy and Wide Angle X-Ray Diffraction.” Journal of Polymer Research, 69, 148-158. doi: https://doi.org/10.1016/j.polymer.2015.05.010.

-

O’Connor, T. C. Andzelm, J. and Robbins, M. O. (2015) “AIREBO-M: A reactive model for hydrocarbons at extreme pressures.” The Journal of Chemical Physics, 142(2), 24903-24903. doi: http://dx.doi.org/10.1063/1.4905549.

-

Rahman, R. and Foster, J. (2015) “A molecular dynamics based investigation of thermally vibrating graphene under different boundary conditions.” Physica E: Low-dimensional Systems and Nanostructures, 72, 25-47. doi: https://doi.org/10.1016/j.physe.2015.04.007.

-

Rahman, R. and Foster, J. (2015) “Peridynamic theory of solids from the perspective of classical statistical mechanics.” Physica A: Statistical Mechanics and its Applications, 437, 162-183. doi: http://dx.doi.org/10.1016/j.physa.2015.05.099.

-

Sockalingam, S. Gillespie, J. and Keefe, M. (2015) “Dynamic modeling of Kevlar KM2 single fiber subjected to transverse impact.” International Journal of Solids and Structures, 67, 297-310. doi: https://doi.org/10.1016/j.ijsolstr.2015.04.031.

-

Yeh, I. Andzelm, J. and Rutledge, G. (2015) “Mechanical and Structural Characterization of Semicrystalline Polyethylene under Tensile Deformation by Molecular Dynamics Simulations.” Macromolecules, 48(12), 4228-4239. doi: http://dx.doi.org/10.1021/acs.macromol.5b00697.

2014

-

Chantawansri, T. and Sliozberg, Y. (2014) “Computational study of the morphology and mechanical properties of dilute ABC triblock copolymers.” Korea-Australia Rheology Journal, 26(1), 49-61. doi: http://dx.doi.org/10.1007/s13367-014-0006-4.

-

Cole, D. and Strawhecker, K. (2014) “An improved instrumented indentation technique for single microfibers.” Journal of Materials Research, 29(9), 1104-1112. doi: http://dx.doi.org/10.1557/jmr.2014.83.

-

Lopatnikov, S. and Gillespie, J. (2014) “Simple analytical model for fiber tensile failure due to droplet impact.” Journal of Applied Physics, 115(6), 63511-63511. doi: http://dx.doi.org/10.1063/1.4863207.

-

McAllister, Q. Gillespie, J. and VanLandingham, M. (2014) “The energy dissipative mechanisms of particle-fiber interactions in a textile composite.” Journal of Composite Materials, 48(28), 3553-3567. doi: http://dx.doi.org/10.1177/0021998313511651.

-

Nilakantan, G. Merrill, R. Keefe, M. Gillespie, J. and Wetzel, E. (2014) “Experimental investigation of the role of frictional yarn pull-out and windowing on the probabilistic impact response of kevlar fabrics.” Composites Part B: Engineering, 68, 215-229. doi: https://doi.org/10.1016/j.compositesb.2014.08.033.

-

Rahman, R. and Foster, J. (2014) “Bridging the length scales through nonlocal hierarchical multiscale modeling scheme.” Computational Materials Science, 92, 401-415. doi: http://dx.doi.org/10.1016/j.commatsci.2014.05.052.

-

Rahman, R. and Foster, J. (2014) “Deformation mechanism of graphene in amorphous polyethylene: A molecular dynamics based study.” Computational Materials Science, 87, 232-240. doi: https://doi.org/10.1016/j.commatsci.2014.02.023.

-

Rahman, R. Haque, A. and Foster, J. (2014) “A Multiscale Modeling Scheme Based on Peridynamic Theory.” International Journal for Multiscale Computational Engineering, 12(3), 223-248. doi: http://doi.org/10.1615/IntJMultCompEng.2014007954.

-

Sanborn, B. and Weerasooriya, T. (2014) “Quantifying damage at multiple loading rates to Kevlar KM2 fibers due to weaving, finishing, and pre-twist.” International Journal of Impact Engineering, 71, 50-59. doi: https://doi.org/10.1016/j.ijimpeng.2014.04.005.

-

Strawhecker, K. and Cole, D. (2014) “Morphological and local mechanical surface characterization of ballistic fibers via AFM.” Journal of AppliedPolymer Science, 131(19), 1-1. doi: http://dx.doi.org/10.1002/app.40880.

2013

-

Grujicic, M. Pandurangan, B. Snipes, J. Yen, C. and Cheeseman, B. (2013) “Multi-Length Scale-Enriched Continuum-Level Material Model for Kevlar®-Fiber-Reinforced Polymer-Matrix Composites.” Journal of Materials Engineering and Performance, 22(3), 681-695. doi: http://dx.doi.org/10.1007/s11665-012-0329-6.

-

McAllister, Q. Gillespie, J. and VanLandingham, M. (2013) “The influence of surface microstructure on the scratch characteristics of Kevlar fibers.” Journal of Materials Science, 48(3), 1292-1302. doi: http://dx.doi.org/10.1007/s10853-012-6872-6.

-

McAllister, Q. Gillespie, J. and VanLandingham, M. (2013) “The sub-micron scale energy dissipative deformation mechanisms of Kevlar fibrils.” Journal of Materials Science, 48(18), 6245-6261. doi: http://dx.doi.org/10.1007/s10853-013-7422-6.

-

Nilakantan, G. and Gillespie, J. (2013) “Yarn pull-out behavior of plain woven Kevlar fabrics: Effect of yarn sizing, pullout rate, and fabric pre-tension.” Composite Structures, 101, 215-224. doi: https://doi.org/10.1016/j.compstruct.2013.02.018.

-

Nilakantan, G. Wetzel, E. Bogetti, T. and Gillespie, J. (2013) “A deterministic finite element analysis of the effects of projectile characteristics on the impact response of fully clamped flexible woven fabrics.” Composite Structures, 95, 191-201. doi: https://doi.org/10.1016/j.compstruct.2012.07.023.

-

Rahman, R. Foster, J. and Haque, A. (2013) “Molecular dynamics simulation and characterization of graphene–cellulose nanocomposites.” The Journal of Physical Chemistry A, 117(25), 5344-5353. doi: https://doi.org/10.1021/jp402814t.

-

Sirk, T. Khare, K. Karim, M. Lenhart, J. Andzelm, J. McKenna, G. and Khare, R. (2013) “High strain rate mechanical properties of a cross-linked epoxy across the glass transition.” Polymer, 54(26), 7048-7057. doi: https://doi.org/10.1016/j.polymer.2013.10.051.

-

Sliozberg, Y. and Chantawansri, T. (2013) “Computational study of imperfect networks using a coarse-grained model.” The Journal of Chemical Physics, 139(19), 194-904. doi: http://dx.doi.org/10.1063/1.4832140.

2012

-

Chantawansri, T. Sliozberg, Y. Andzelm, J. and Hsieh, A. (2012) “Coarse-grained modeling of model poly(urethane urea)s: Microstructure and interface aspects.” Polymer, 53(20), 4512-4524. doi: https://doi.org/10.1016/j.polymer.2012.07.056.

-

Grujicic, M. Hariharan, A. Pandurangan, B. Yen, C. Cheeseman, B. Wang, Y. Miao, Y. and Zheng, J. (2012) “Fiber-Level Modeling of Dynamic Strength of Kevlar® KM2 Ballistic Fabric.” Journal of Materials Engineering and Performance, 21(7), 1107-1119. doi: http://dx.doi.org/10.1007/s11665-011-0006-1.

-

McAllister, Q. Gillespie, J. and VanLandingham, M. (2012) “Evaluation of the three-dimensional properties of Kevlar across length scales.” Journal of Materials Research, 27(14), 1824-1837. doi: https://doi.org/10.1557/jmr.2012.80.

-

McAllister, Q. Gillespie, J. and VanLandingham, M. (2012) “Nonlinear indentation of fibers.” Journal of Materials Research, 27(1), 197-213. doi: https://doi.org/10.1557/jmr.2011.336.

-

Nilakantan, G. and Gillespie, J. (2012) “Ballistic impact modeling of woven fabrics considering yarn strength, friction, projectile impact location, and fabric boundary condition effects.” Composite Structures, 94(12), 3624-3634. doi: https://doi.org/10.1016/j.compstruct.2012.05.030.

-

Nilakantan, G. Keefe, M. Wetzel, E. Bogetti, T. and Gillespie, J. (2012) “Effect of statistical yarn tensile strength on the probabilistic impact response of woven fabrics.” Composites Science and Technology, 72(2), 320-329. doi: https://doi.org/10.1016/j.compscitech.2011.11.021.

-

Nilakantan, G. Wetzel, E. Bogetti, T. and Gillespie, J. (2012) “Finite element analysis of projectile size and shape effects on the probabilistic penetration response of high strength fabrics.” Composite Structures, 94(5), 1846-1854. doi: https://doi.org/10.1016/j.compstruct.2011.12.028.

-

Sirk, T. Slizoberg, Y. Brennan, J. Lisal, M. and Andzelm, J. (2012) “An enhanced entangled polymer model for dissipative particle dynamics.” The Journal of Chemical Physics, 136(13), 134-903. doi: https://doi.org/10.1063/1.3698476.

-

Sliozberg, Y. and Andzelm, J. (2012) “Fast protocol for equilibration of entangled and branched polymer chains.” Chemical Physics Letters, 523, 139-143. doi: https://doi.org/10.1016/j.cplett.2011.12.040.

-

Sliozberg, Y. Sirk, T. Brennan, J. and Andzelm, J. (2012) “Bead-spring models of entangled polymer melts: Comparison of hard-core and soft-core potentials.” Journal of Polymer Science Part B: Polymer Physics, 50(24), 1694-1698. doi: http://dx.doi.org/10.1002/polb.23175.